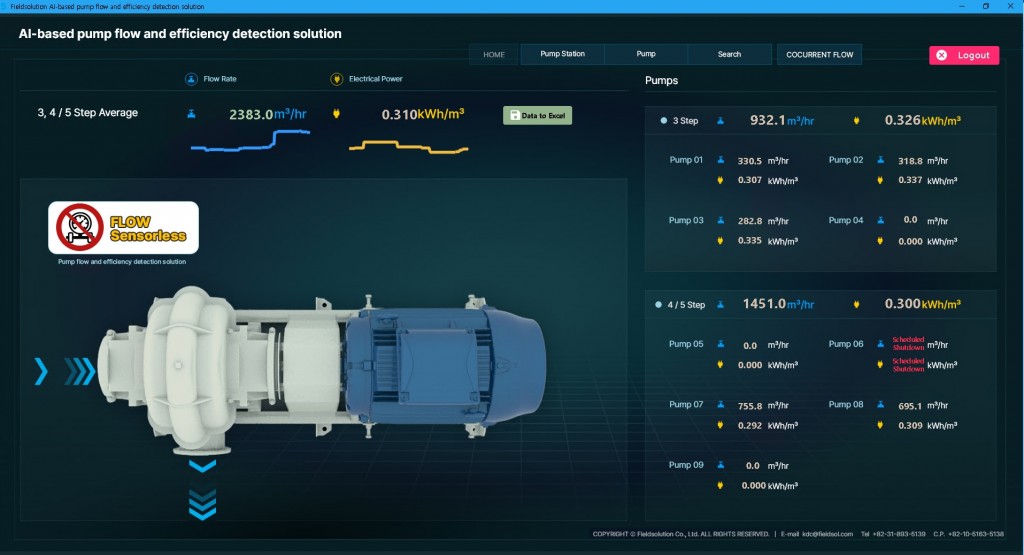

Fieldsolution Co., Ltd. registers [AI-based pump flow and efficiency detection solution] on the solution business platform operated by the Korea Water Resources Corporation.

Configuration

1. Connectivity: Collecting data in real time

2. Database: Missing, outlier handling, heterogeneous time synchronization, SQL Server

3. AI Engine: EDA, Performance Indicators, Baseline AI Model

4. Dash reports and APIs: FHD screen dashboard, API, SNS and email alarms

* AI Model Development: Korea Water Resources Corporation has secured data for 134 sensor data of iWater Node HMI Tag 1,010,950 (1GB) and compared 10,000 cases of pump performance evaluation data (0.001GB) to secure the reliability of process sensors. These secured data build a model by applying supervised learning and multivariate nonlinear regression model

Supplier and Purchaser

Supplier: Field Solutions Co., Ltd

Purchaser: Pump Care Co., Ltd

Before: It is impossible to control the pump flow rate to increase efficiency due to manual setting and continuous fixation by experts twice a year (conducted twice a year, 8 hours * 60 minutes per day => 480 minutes)

After: The cost was reduced as AI analyzed the pump operation efficiency. (Reduced the flow sensor cost per pump by 26 million won), and the lead time for determining individual pump flow rates was shortened. (480 minutes → 10 minutes)

Reference

Testing and field demonstration

After obtaining access to SCADA Node HMI Tag related to resin water purification plant and pump pressurization pump from Korea Water Resources Corporation, data pipeline was secured through custom Connectivity SW. The AI solution applied a nonlinear regression MLP (Multilayer Perceptron Neural Network) model after applying principal component for a number of pump operation and monitoring variables. The AI performance index was carried out by calculating the error between the AI detection flow rate value and the actual flow rate as a mean absolute percentage error (MAPE) and reducing it from 100% of the maximum performance. The operation was carried out from August 2022 to December 2023, and it is scheduled to be operated continuously.

Expectation effectiveness

Shortening lead time for determining individual pump flow rate (480 minutes → 10 minutes) and reducing cost by 26 million won per pump.

Enhance work efficiency with real-time monitoring

https://www.wateround.kr/wq/index.do?w2xPath=/ui/index.xml

Related Posts

Real-time control of flow rate for each water treatment pump with AI

[caption id="attachment_292508" align="aligncenter" width="640"] Real-time control of flow rate for…

Active support for water industry companies entering the global market

[caption id="attachment_292504" align="aligncenter" width="640"] Active support for water industry companies…

Field Solutions Co., Ltd. participated in the Smart City Expo World Congress in Barcelona, Spain (2023).

Field Solutions Co., Ltd. participated in the Smart City Expo…