– AI-based flow predictable valve development improves control accuracy by more than 80%

– AI-based pumps save more than 300 million won per year in power consumption

Along with the growth of the smart water grid business, development solutions that are undergoing “field solutions” are drawing attention. Smart Water Grid is an intelligent water management system to overcome the limitations of the existing water resource management system, which combines water management technology and advanced information and communication technology (ICT) to compensate for weaknesses in existing facilities and build high-efficiency infrastructure systems.

Field Solution is developing two large artificial intelligence solutions this year. It is a “valve solution capable of AI-based flow prediction” and an “AI-based pump combination individual flow efficiency improvement solution.” The development of these solutions is supported by the “AI Convergence Regional Specialization Industry Support Project” organized by the Ministry of Science and ICT and the Information and Communication Industry Promotion Agency (NIPA). Field Solution is developing to meet the needs of two demanding companies by participating in the AI convergence support project that supports the convergence and utilization of artificial intelligence in local specialized industries.

The “valve solution capable of AI-based flow prediction” is to improve valve performance by adding a prediction function to the existing decompression valve proportional control (PI) and realize a function that can perform a pre- or real-time fault diagnosis alarm. The pressure relief valve plays a role in lowering water pressure, and the leakage rate is adjusted by lowering the pipeline pressure during low water consumption and normalizing the pipeline pressure during high water consumption. Artificial intelligence can control pressure relief valves much more efficiently than humans do by learning user pattern analysis and various abnormal situations in the field through deep learning.

Previously, pressure relief valve inspection was carried out annually, but as the solution is developed and inspected once every 10 minutes, accuracy is expected to improve by more than 80%, reduce annual valve control costs, and generate 150 million won in profits.

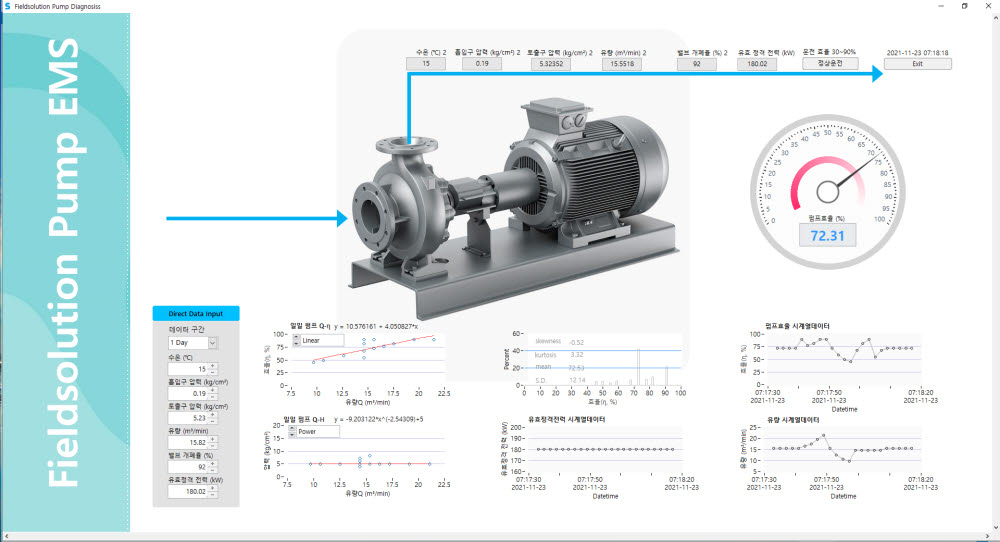

“AI-based pump combination individual flow efficiency improvement solution” is designed to accurately apply variable amount and variable flow rate by impeller when rated amount and flow rate manufactured by manufacturer vary depending on field environment by analyzing pump environment. In addition, it will have a monitoring system that can frequently check whether the pump performance is abnormal by allowing managers to conduct performance evaluations conducted by experts in real time.

*Source: https://view.asiae.co.kr/article/2022112813361448959

Related Posts

Fieldsolution Co., Ltd. registers [AI-based pump flow and efficiency detection solution] on the solution business platform operated by the Korea Water Resources Corporation.

Fieldsolution Co., Ltd. registers [AI-based pump flow and efficiency detection…

Real-time control of flow rate for each water treatment pump with AI

[caption id="attachment_292508" align="aligncenter" width="640"] Real-time control of flow rate for…

Active support for water industry companies entering the global market

[caption id="attachment_292504" align="aligncenter" width="640"] Active support for water industry companies…